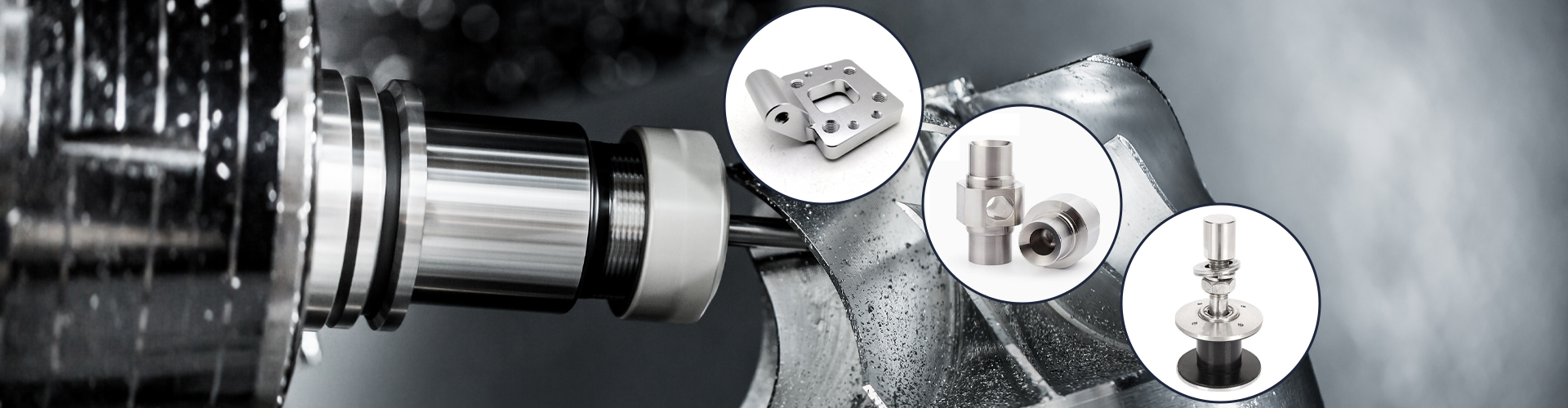

SHENGFA Hardware, who was established in 2007 and located in Ningbo China, has been committed to providing high-quality ferrous and non-ferrous precision investment casting parts to the customer from all of the world. SHENGFA’s one-stop service manufacturing process includes everything from design for manufacturing to in-house casting, CNC machining, and forging. Our vertically integrated manufacturing process significantly reduces cost and lead times without sacrificing products’ quality. When design complexity, tolerance control and repeatability are the most important issues, precision investment casting by far is considered as the most cost-effective solution compared to other methods of producing metal parts and assemblies.

SHENGFA Hardware is one of the largest lost wax investment casting parts suppliers in Ningbo China. By means of the lost wax method, high quality investment castings are produced with complex shapes and high dimensional accuracy. What’s more, this investment method offers a great degree of freedom in design and material choice. Your specific requirements and demands can be involved into the castings. By our over 15 years long experience with the lost wax investment casting techniques, we can assure you that our lost wax investment casting parts we provide are the most cost-effective with high quality. Choosing the right manufacturing method for your product order is important. And choosing the right manufacturing business partner is also very important. Contact us to take your first right step.

Specializing in manufacturing of forklift investment castings, SHENGFA Hardware is always focus on being a world class manufacturer and supplier in Ningbo China. We have 3 major facilities, investment casting, CNC machining and forging, which enable our company can provide full solutions for our customer from Europe, America, Japan and other countries all over the world. Besides forklift investment castings, we also provide investment castings for railway, automobile, construction machinery and agricultural machinery. With more than 15 years of design and production experience, we have the ability to help our customers optimize product design, provide better solutions and reduce costs.

SHENGFA Hardware is using the precision lost wax investment castings method to prototype and produce products for the automobile, commercial, medical, and shipbuilding industries. We pour aluminum, stainless steel, bronze, and steel alloys to casting the products that satisfy our dear customers. We have been in the investment casting business as a manufacturer since 2007 in Ningbo China. During this 15 years history, we are always striving to have the highest quality products in the industry while continuously improving and expanding. SHENGFA uses our own tooling shop to create your lost wax investment castings as well as similar casting styles or specifications.

SHENGFA Hardware is a reliable source for aluminum investment castings information and leading aluminum alloy investment castings factory & supplier in Ningbo China. Aluminum and aluminum alloys are among the most regular materials for investment casting; Other castable metal may be used such as copper, brass or steel. One of the benefits for the casting parts is that they require little or even no machining or finishing after they are cast. SHENGFA Hardware was established in 2007, since then we have been driven to remain a cut above the competition in investment castings and other business we do. We have our own tooling shop filled with state-of-the-art testing machines. We ensure perfect results and products every time. It is our mission to establish lifelong relationships with our customers by providing good quality products at low cost and on time delivery. Contact us to know more about our aluminum alloy investment castings service today.

Founded in 2007, SHENGFA Hardware is a well-known copper alloy investment casting manufacturer in Ningbo China who offers a full range of services from innovative design and engineering to sourcing and production using best in class quality control methods at a cost-effective manner. Focus areas include CNC machining, investment castings, and forging. With our diverse capabilities and depth of experience over 15 years, we will help to make your design and concept into reality. Copper alloys are metals that have the predominant component of copper. Copper alloy investment casting is incredibly versatile, so it is used in a large variety of applications, such as s plumbing, marine and electrical.